A Soraluce Bridge Mill Machining Soraluce Castings

It's the mother of all machines, literally. A machine that makes major components for machines. Big machines! This Soraluce PRW17000 bridge-type milling machine has recently been installed at Goimek, where they machine parts up to 100 tons, including the base, column, ram and other components for Soraluce milling, boring, multitasking machines.

Soraluce PRW17000 Bridge Mill Spec:

• 669.29" (17.000 mm) longitudinal travel

• 255.91" (6.500 mm) crossrail travel

• 78.74" (2.000 mm) vertical (RAM) travel

• 59.06" (1.500 mm) cross beam vertical travel

• 8.500 x 4.500 mm Table #1

• 6.000 x 4.500 mm Table #2

Shaping Aerospace Progress

Discover how to enhance precision and efficiency in the machining of aerospace and aeronautical components by downloading our latest whitepaper. Gain insights into solutions for machining airframes, engines, and landing gear components. Explore advanced technologies such as 5-axis machining, vibration control, and automation, and learn how these innovations optimize processes, and increase reliability. Photo credit: Blue Origin, one of the many customers benefiting from Soraluce technology.

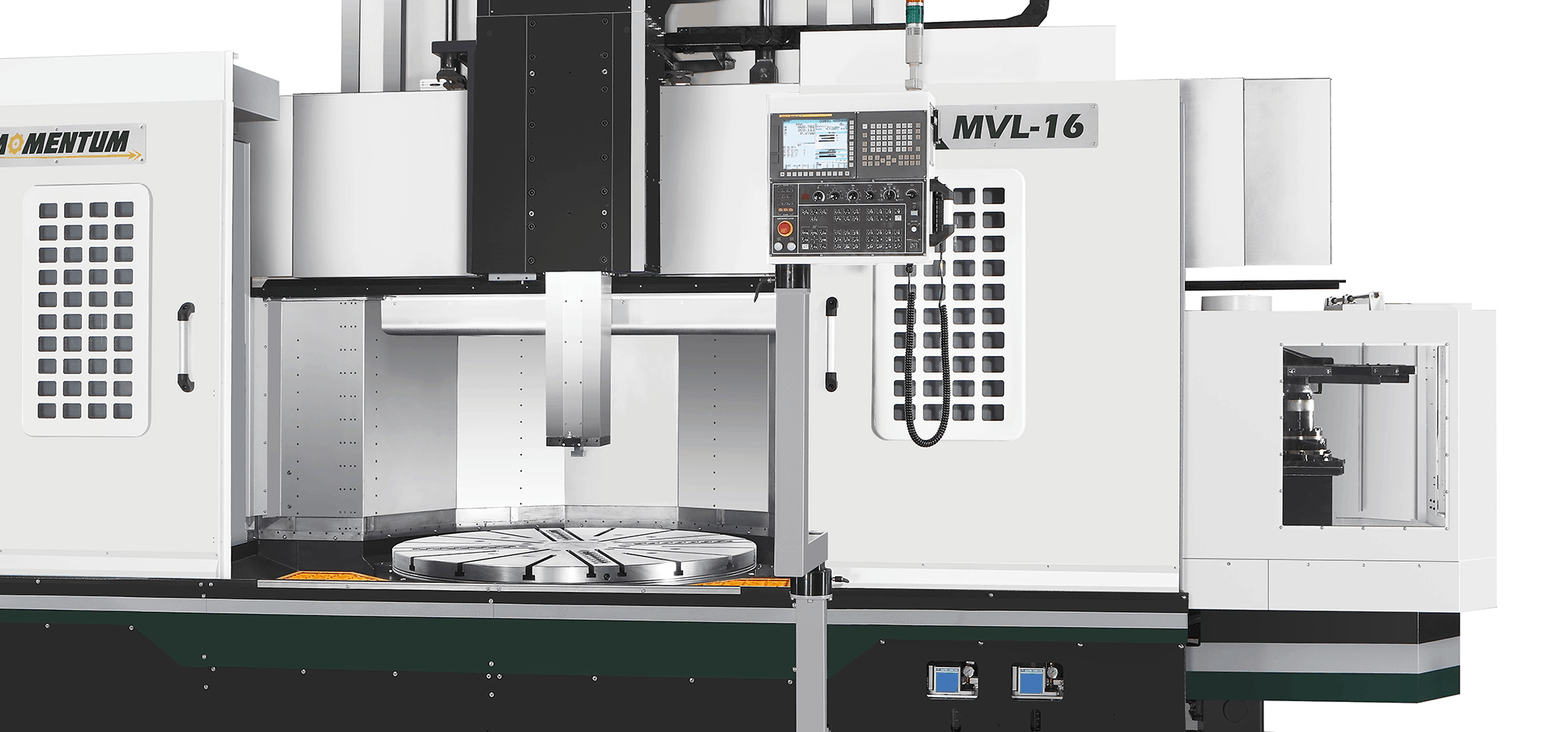

Momentum Lathe Turning Large Parts for Off Shore Oil Exploration in Texas

“The Momentum MVL-16M lathe’s 63-inch chuck, 78-inch max turning diameter, and 63-inch max turning height gives Fabcorp the ability to perform full mill/turn work,” states Oscar Hernandez, Plant Manager at Fabcorp. “We've turned up to 3/8s, radial cuts on tough materials and have no complaints, the machine pushes it with the 75 horsepower main spindle.”

Introducing the GEMINIS GM9i Multi-Process Turning Center

In this machine walkaround video, Doug Schulte, aka the Machine Tool Google, goes over the features of a Geminis GM9i Multi-Process Turning Center on the factory floor in Spain, before being shipped to a US based steel mill. Doug shares many of the design features that were developed specifically for the machinist, to provide easy, safe access to oversized parts being machined.

Milling, Threading, Turning and Grinding Components Complete on a SORALUCE

Coffin Turbo Pump has realized a 35% to 40% reduction in machining time by CNC milling, threading, turning and grinding in their new SORALUCE TAM 25 multitasking machining center. The SORALUCE machining center is the single largest investment made in their plant in over 20 years.

“It’s a game changer” - Jim Kinneary, President and CEO

FIBA Industries Boosts Productivity with Soraluce Multitasking Machine

Enjoy this interview with Matt Sprogna, Director of Operations at FIBA Industries in Littleton, MA to learn how they've increased productivity on large storage vessels / tanks with the recent addition of a Soraluce FLP 14000 floor-type milling, boring, multitasking machining center