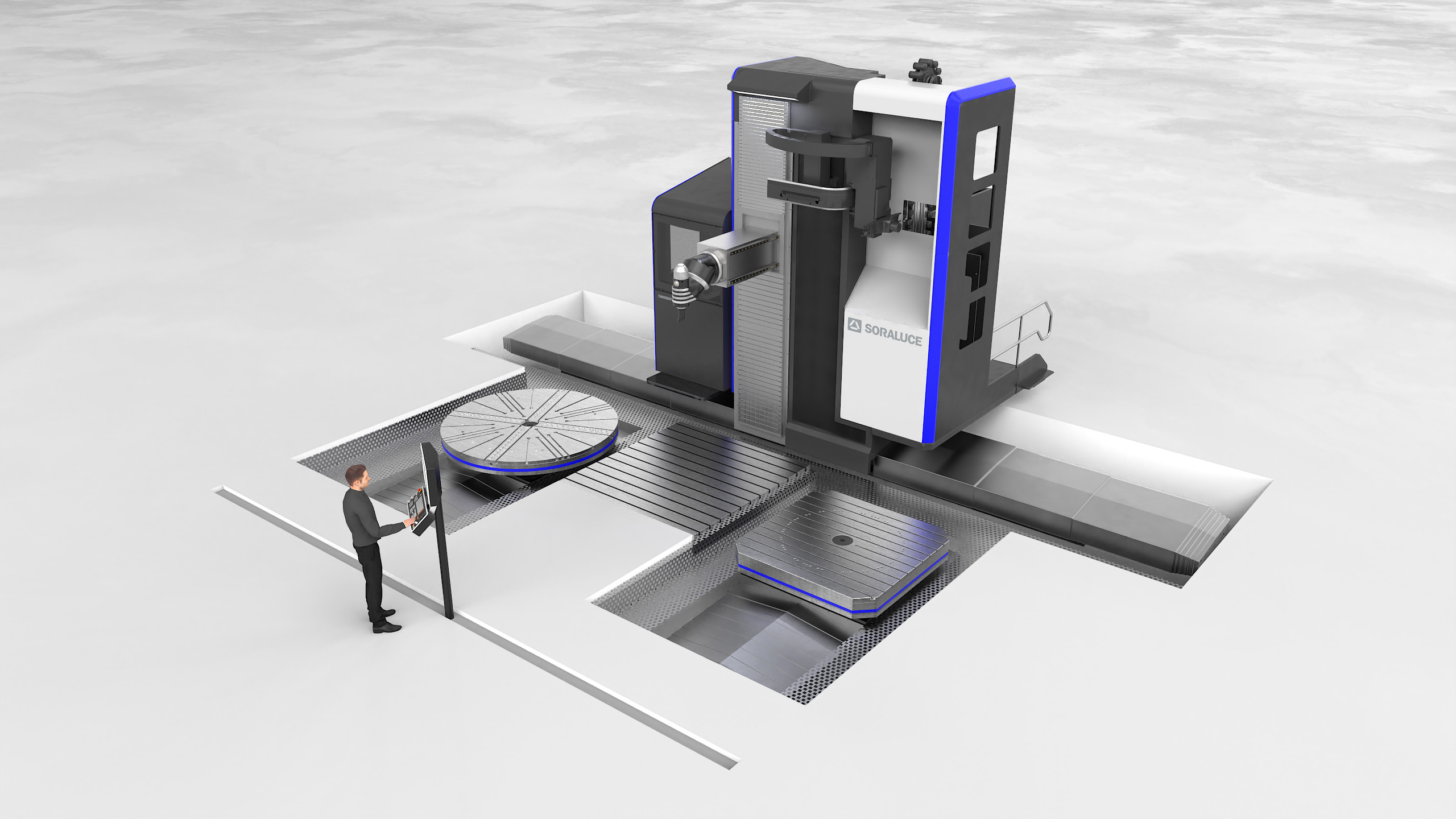

Configure the Star of IMTS 2026

Make the IMTS Soraluce FP60 your own. A 5-axis Soraluce FP60 floor-type milling, boring and multitasking machine scheduled to premiere at IMTS 2026 is currently in build, giving you a limited window to configure this machine around your unique manufacturing needs. From table options, including 4th-axis milling or multitasking tables, to additional universal heads and an automatic head changer, many key features can still be specified by you!

Take advantage of this unique opportunity which will ultimately place a large capacity 5-axis on your shop floor immediately after the show in September!

Cutting Production Time from Days to Hours

“We went from taking days to machine a part to doing it in under an hour,” says Queen. “Now we can turn jobs around faster, keep our customers happier, and take on more work with the added capacity.”

Highland Manufacturing president Christian Queen shares how his shop transformed production by replacing an aging jig bore with a Soraluce TAD25 6-axis (4+2) machining center. Featuring a universal head and built-in rotary table, the TAD25 machines all six sides of a prismatic part in a single setup—top, bottom, front, back, left, and right.

A Soraluce Bridge Mill Machining Soraluce Castings

It's the mother of all machines, literally. A machine that makes major components for machines. Big machines! This Soraluce PRW17000 bridge-type milling machine has recently been installed at Goimek, where they machine parts up to 100 tons, including the base, column, ram and other components for Soraluce milling, boring, multitasking machines.

Soraluce PRW17000 Bridge Mill Spec:

• 669.29" (17.000 mm) longitudinal travel

• 255.91" (6.500 mm) crossrail travel

• 78.74" (2.000 mm) vertical (RAM) travel

• 59.06" (1.500 mm) cross beam vertical travel

• 8.500 x 4.500 mm Table #1

• 6.000 x 4.500 mm Table #2

Shaping Aerospace Progress

Discover how to enhance precision and efficiency in the machining of aerospace and aeronautical components by downloading our latest whitepaper. Gain insights into solutions for machining airframes, engines, and landing gear components. Explore advanced technologies such as 5-axis machining, vibration control, and automation, and learn how these innovations optimize processes, and increase reliability. Photo credit: Blue Origin, one of the many customers benefiting from Soraluce technology.

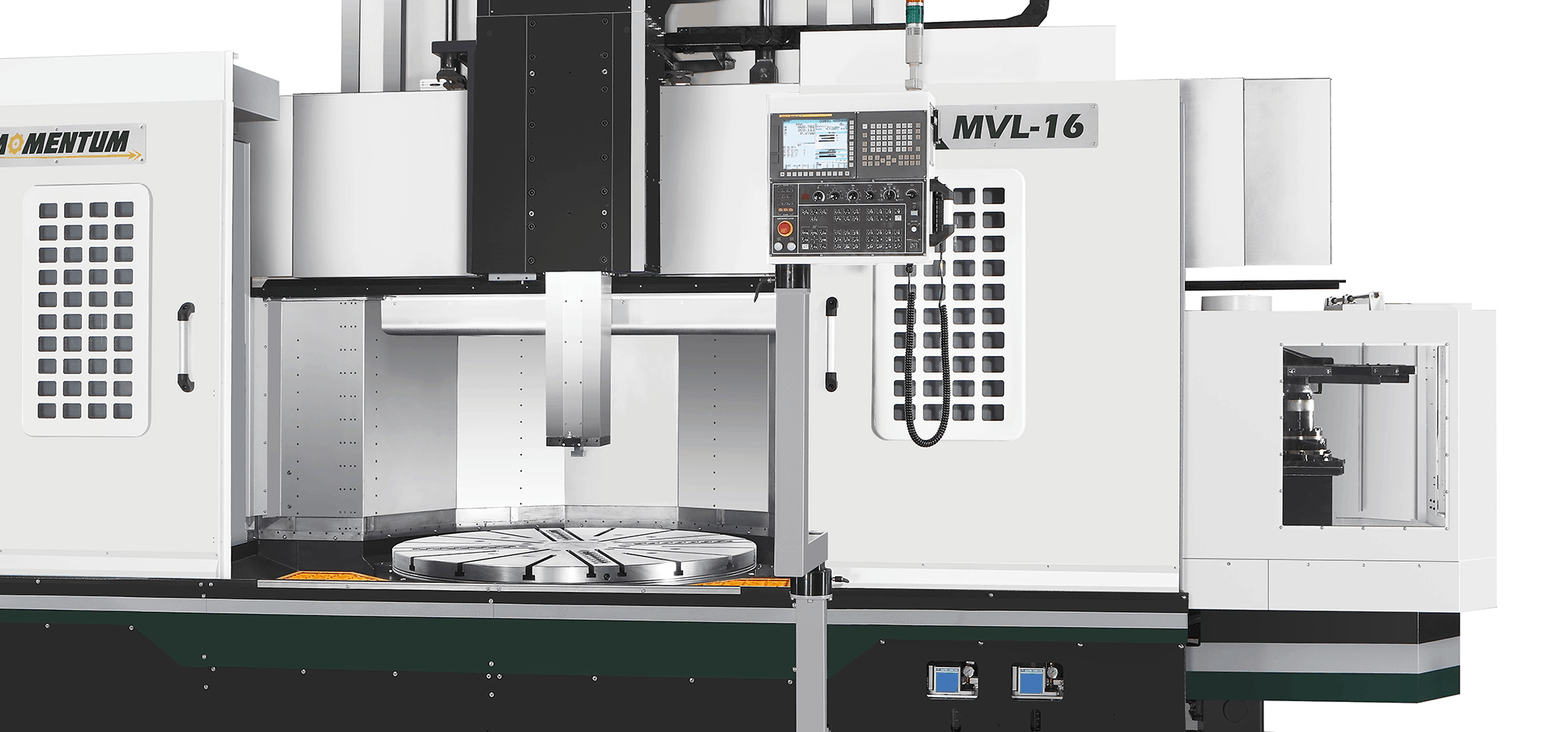

Momentum MVL Opens Up Capacity at Highland Manufacturing!

Christian Queen, President and owner of Highland Manufacturing, based in Manchester CT, discusses the move from a Bullard manual VTL to a fully enclosed CNC lathe that operates more like a modern machining center. The Momentum MVL-10HD is a CNC operated vertical turning lathe featuring a full enclosure that contains large chips and coolant for a safer shop floor, combined with a full wrap cast iron base that provides the rigidity to take deep cuts.

Introducing the GEMINIS GM9i Multi-Process Turning Center

In this machine walkaround video, Doug Schulte, aka the Machine Tool Google, goes over the features of a Geminis GM9i Multi-Process Turning Center on the factory floor in Spain, before being shipped to a US based steel mill. Doug shares many of the design features that were developed specifically for the machinist, to provide easy, safe access to oversized parts being machined.

Milling, Threading, Turning and Grinding Components Complete on a SORALUCE

Coffin Turbo Pump has realized a 35% to 40% reduction in machining time by CNC milling, threading, turning and grinding in their new SORALUCE TAM 25 multitasking machining center. The SORALUCE machining center is the single largest investment made in their plant in over 20 years.

“It’s a game changer” - Jim Kinneary, President and CEO

FIBA Industries Boosts Productivity with Soraluce Multitasking Machine

Enjoy this interview with Matt Sprogna, Director of Operations at FIBA Industries in Littleton, MA to learn how they've increased productivity on large storage vessels / tanks with the recent addition of a Soraluce FLP 14000 floor-type milling, boring, multitasking machining center