Floor Type, Bridge Type, and Bed Type Milling, Boring, Multitasking Machines

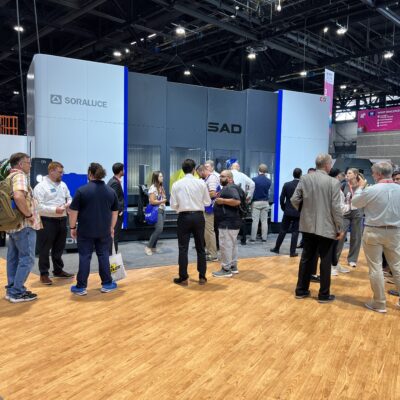

About Soraluce

SORALUCE is a technology-driven leader in the design and manufacturing of highly configurable milling, boring, and multitasking machines, engineered to deliver precise machining of large, complex parts. With a strong emphasis on efficiency and reliability, SORALUCE machines are built to meet the demands of industries that require high-precision, heavy-duty machining solutions

Configurations include 5-axis bed-type and floor-type milling, boring, multitasking machining centers, bridge and gantry-type portal machines, and vertical turning centers. Work-area configurations with fixed floor plates, rotary and mill/turn table options, as well as over 300 different spindle heads are available to adapt to your unique application.

Shaping Aerospace Progress

Discover how to enhance precision and efficiency in the machining of aerospace and aeronautical components by downloading our latest whitepaper. Gain insights into solutions for machining airframes, engines, and landing gear components. Explore advanced technologies such as 5-axis machining, vibration control, and automation, and learn how these innovations optimize processes, and increase reliability. Photo credit: Blue Origin, one of the many customers benefiting from Soraluce technology

Boring Mills

Rigid and Precise

SORALUCE unique design boring machines are conceived for efficient multi-face machining of medium and large sized workpieces, ensuring robustness and precision.

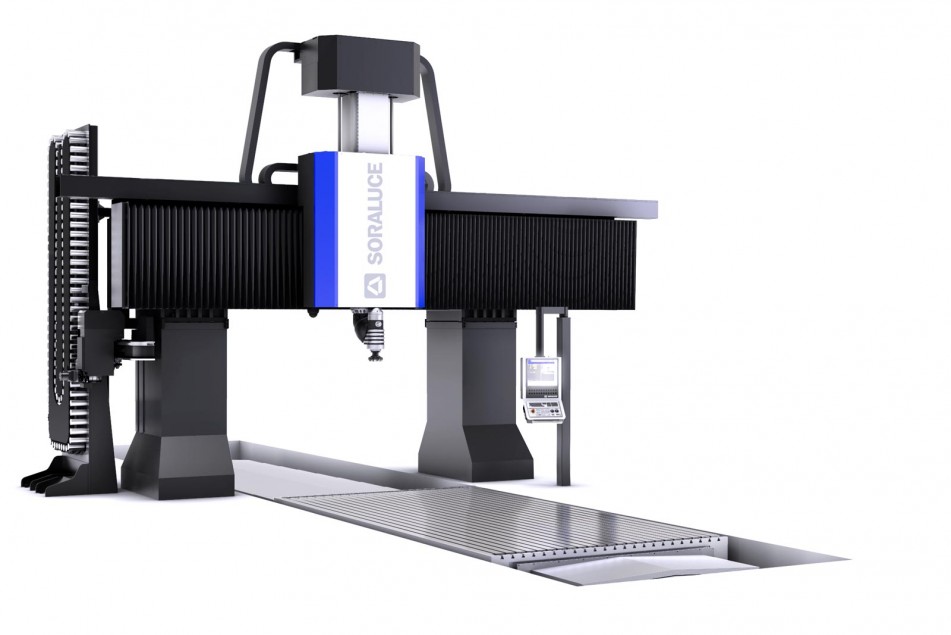

Bridge & Gantry Mills

Precision and Versatility

SORALUCE offers a broad range of Bridge and Gantry milling machines engineered for a broad range of applications for large complex components

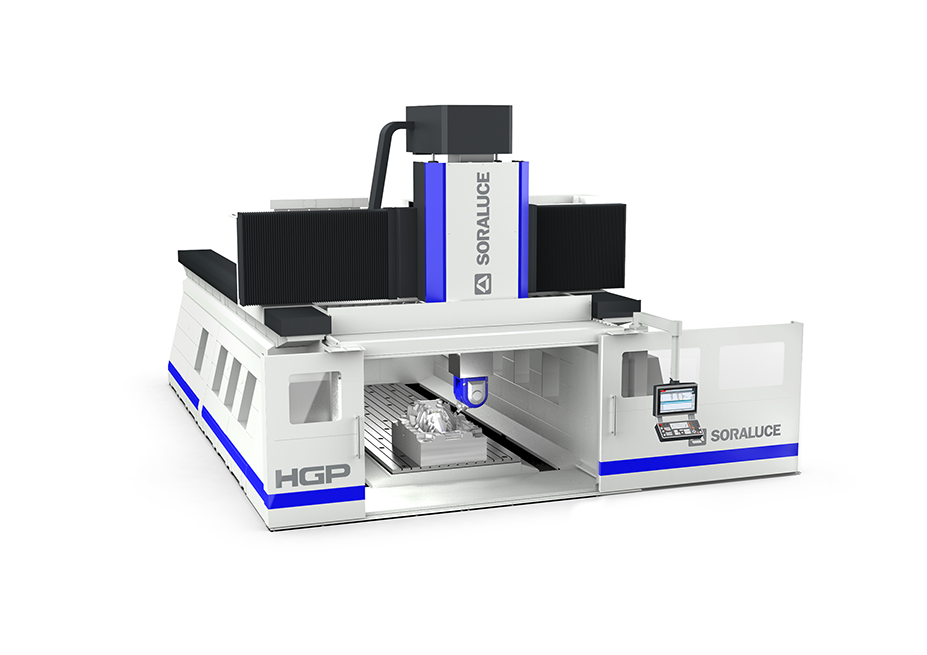

High Rail Gantry

Dynamic Line

Three models delivering high-speed metal removal and superior precision, oriented to sectors like the aerospace or mold & die, ideal for composites, light alloys or steel components.

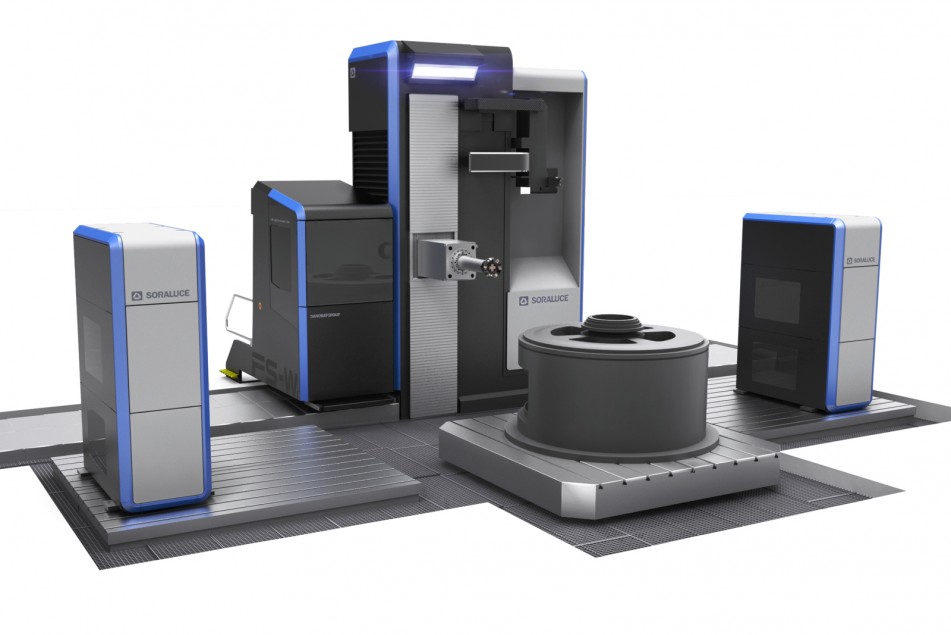

Multitasking Machines

Milling, Turning & Grinding

SORALUCE multitasking machines achieve the highest profitability in the machining of large and technical complex parts.

Milling Machines

Efficiently and Precisely Customised

SORALUCE high precision milling machines have been developed to suit specific applications of our customers, providing the highest reliability and productivity benefits.

Vertical Turning Lathes

Versatility and Productivity

SORALUCE vertical machines create new standards of turning and machining capability for users in the most demanding industries, providing proven performances.

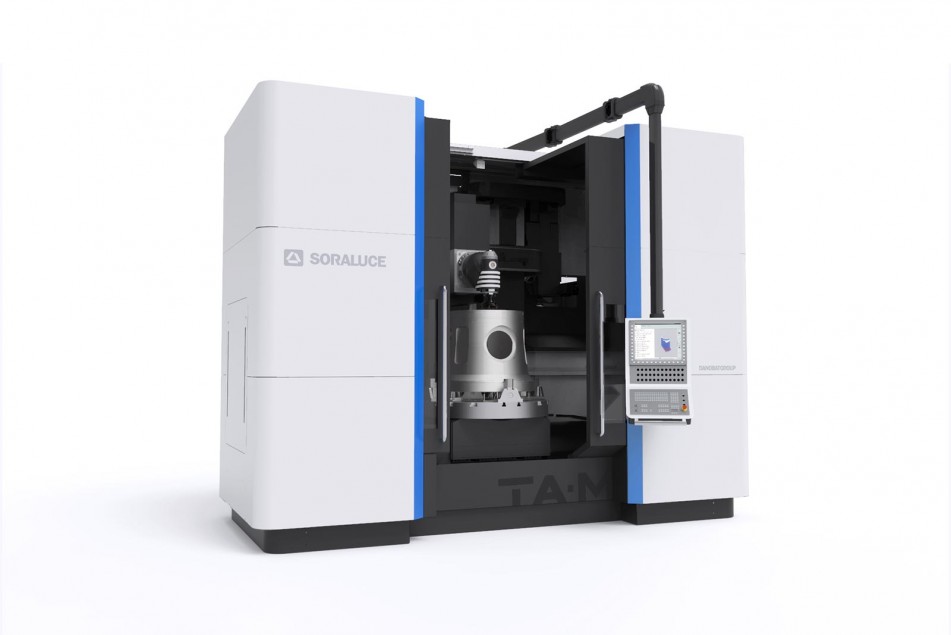

Soraluce TAD25 Multitasking Machine Review with Doug Schulte

Senior Product Manager and Machine Tool Google Doug Schulte does an in-depth review of Soraluce's TAD25 multitasking machining center. The large capacity TAD25 features a built-in rotary table and universal spindle head for 5-axis machining of large, complex, prismatic parts.

Industrial Vehicles Whitepaper

Discover 7 key ways to improve the productivity in the machining of large complex components for industrial vehicles, such as booms, arms, frames, or buckets. Learn how advanced milling & boring solutions, developed by industry leader SORALUCE, significantly reduce machining times and material handling while delivering the highest level of accuracy to exceed this sector’s production challenges.

- Select the solution that best adapts to your volume scenario

- Explore ways to increase productivity

- Add automation for unattended machining

- Integrate your machine into your production management system

- Optimize tool management

- Customize your solution with over 300 spindle head configurations

- Lean on our expertise in machining large complex components

ALL NEW PERFORMANCE LINE

Discover the All-New SORALUCE Performance Line, born to provide the highest reliability and precision along with outstanding flexibility. One structure, three architectures, endless solutions adapted to your machining requirements.

- TA: Bed Type Machining Center

- FA: Floor Type Machining Center

- SA: Fixed Table Travelling Column Machining Center